When Chevrolet started designing ‘Vega’ during the 1970s, one of the main objectives was to keep the cost of the car down around $2,000 in circa-1970 dollars.

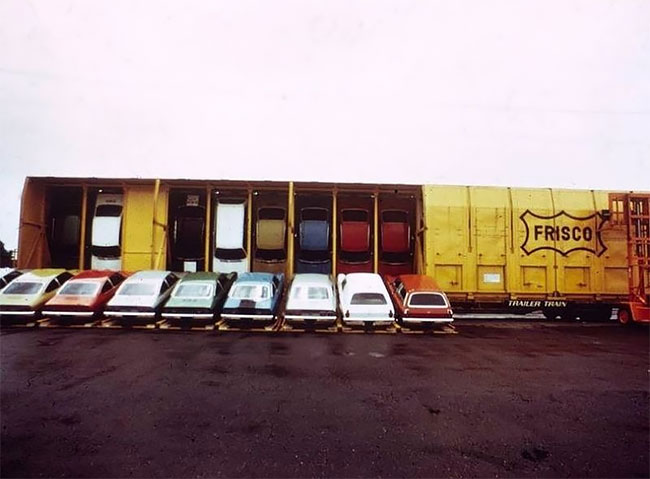

At the time, the freight charge for moving a loaded railroad car from the Lordstown assembly plant to the Pacific coast – the longest distance that cars produced at Lordstown would need to travel – was around $4,800. Since the Vega was a subcompact, it was possible to squeeze three more cars on a railroad car for a total of eighteen, instead of the usual fifteen.

But that still worked out to around $300 per car – a substantial surcharge for a $2000 car. If only Chevrolet could get more Vegas on a railroad car, the cost per unit of hauling them would go down.

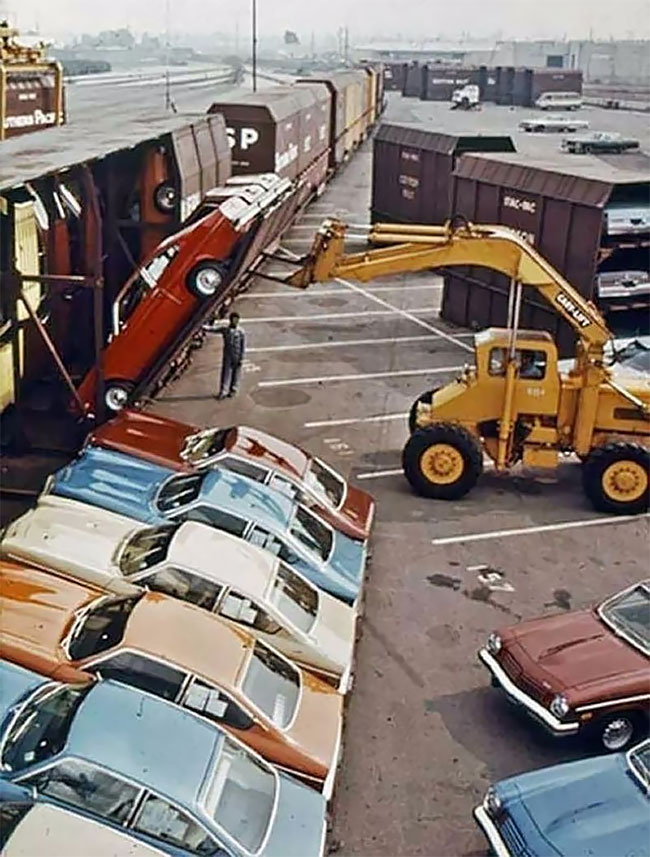

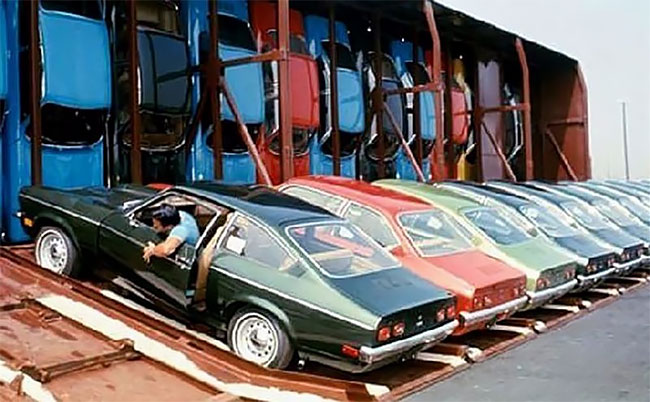

The engineers at GM and the Southern Pacific Railroad came up with a clever solution. Instead of loading the cars horizontally, the Vegas will be placed vertically on a specially designed auto-rack – the Vert-A-Pac. Within the same volume of an 89-foot car, the Vert-A-Pac could hold as many as 30 automobiles instead of 18.

The Vega was hugely popular when it was introduced in 1970 however it quickly earned a reputation for unreliability, rust, safety issues and lousy engine durability.

When the Vega was discontinued, the Vert-A-Pac cars had to be retired as they were too specialized to be used with anything else. The Vert-A-Pac racks were scrapped, and the underlying flatcars went on to other uses.